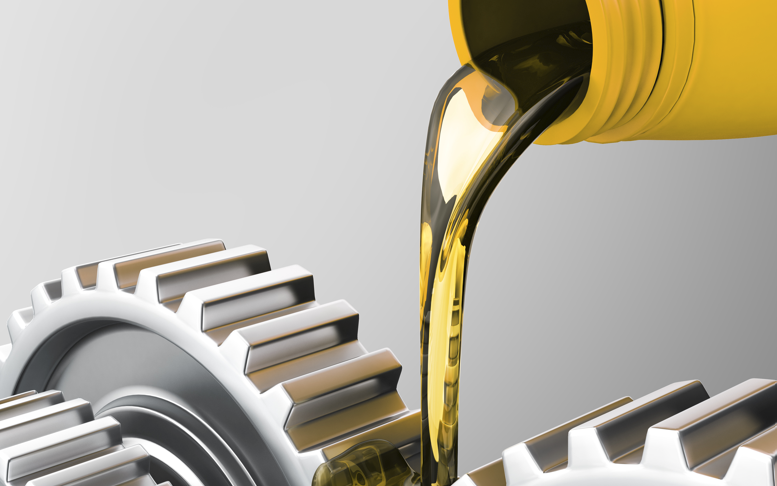

Humans have been using lubricants in some form or the other for thousands of years, starting with the ancient Egyptians.

They, for example, slid granite blocks used to build the pyramids on oiled lumber. They also lubricated the axels of their chariots with calcium soap evidence found dates back to 1400BC. Later the Romans used lubricants from rapeseed oil, olive oil, and animal fats.

The goal of lubricants for centuries has been to reduce friction between surfaces and the added bonus of this was surface protection from oxidation and ultimately corrosion.

Behind every bottle of lubrication oil is a story of engineering. Starting from the type of base oil used, to the selection of additives that are blended into the oil to give the blended product the desired properties of viscosity over extreme temperature ranges, total weight load, and the application environment it can function in (corrosiveness, moisture, dryness, etc.). the desired surface tension expected system pressure and electrical conductivity requirements, the list of parameters is impressive.

Lubrication oils are highly engineered products.

Engineered products are designed to meet specific performance characteristics under various application variables of temperature, pressure, and humidity. Everything about the product is measured and tested, quantified, and analyzed to determine expected performance lifetime and become part of the guarantee of performance you can expect when you use this product.

Measurements of Lubrication Oil properties are done at various times in the product life cycle

Initial manufacture – done by manufacturers and blenders of lubrication oils – these oils are generally classified by intended purpose – motor oil for the automotive market, industrial gear oil lubricants for industrial equipment and the heavy machinery market, hydraulic oils for the automotive and heavy machinery market, the list of applications is impressive

The variety of Lubrication Oils is immense and the main classifications we see are

- Motor Oils

- Gear Oils

- Specialty Oils – application-specific

At ASI we manufacture full suites of Lubrication Oil Standards designed to meet ASTM Methods used by the lube oil manufacturers to qualify their products. Testing and measuring equipment used by lube oil manufacturers need calibration and validation to produce accurate values for the additives present in the blend, or the wear metals and possible contaminants in used oils. then there are specific applications like the measurement of Chlorine in cutting fluid.

The ASI Lubrication Oil Sets

- Cover the following ASTM methods -D4628 -AAS; D4927-XRF; D6443 – XRF; D6481-ICP-OES; D7751-XRF

- Cover the range of elements to be measured in lubrication oils

- Cover the typical concentration ranges that these elements occur in

- Concentrations are randomized to meet the XRF data modeling requirement of independently varying concentrations

- Certificates of Analysis contain values for the Oxygen concentrations of each standard to be used in FP XRF methods

- They are prepared in the default 20cSt base oil unless specified otherwise

- Are good for 18 months to 2 years once opened – see CoA for details

- Can be customized to meet special needs you may have for your products

- A Peek at the History of PCBs - May 9, 2024

- Frequently Asked Questions When Hiring a Digital Marketing Firm - March 22, 2024

- Best Software for On Page SEO - March 22, 2024